Safety in mining industry operations is vital. The consequences of prolonged exposure to certain substances, not to mention incidents, can be serious both in terms of human, environmental and social impacts, and economically. Balancing essential safety aspects with competitive pressures can however be challenging for mine operators. Harsh operating environments can also make monitoring difficult. The Endress+Hauser portfolio offers mining safety enhancement with optimal operational efficiency.

Legfontosabb tények

7,751

injuries caused by accidents

were recorded in 2018 by the members of the International Council on Mining & Metals

Enhanced inventory monitoring

High performance inventory management is as relevant in the mining industry as in any other. However, monitoring dangerous substances such as chemicals, explosives, or acids from storage to transfer to production is a demanding task. When aiming to detect potential losses, measurement of multiple parameters such as level, flow, pressure, and temperature is vital.

Our expertise in the field

Endress+Hauser offers a comprehensive portfolio to cover multiple parameters.

- Monitor all essential parameters to avert losses

- Reduce the risk of inconsistencies caused by different interfaces

- Streamline measuring technologies for cost efficiencies

Dependable remote monitoring

Closely monitoring hazardous processes whilst avoiding the exposure of personnel to risk is a complex dichotomy.

Our expertise in the field

Endress+Hauser offers a broad range of digital sensors and communications to enable reliable remote control of vital parameters, reducing risk to workers whilst sustaining production performance.

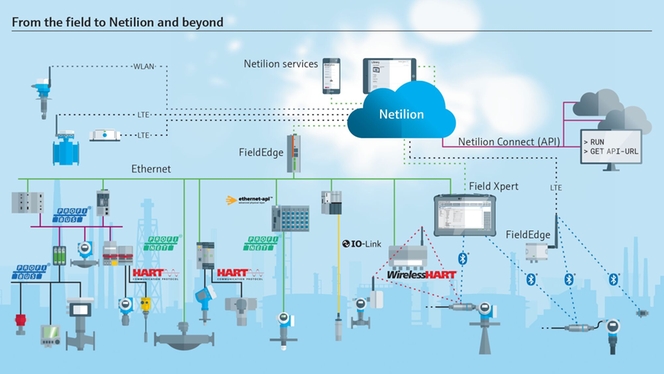

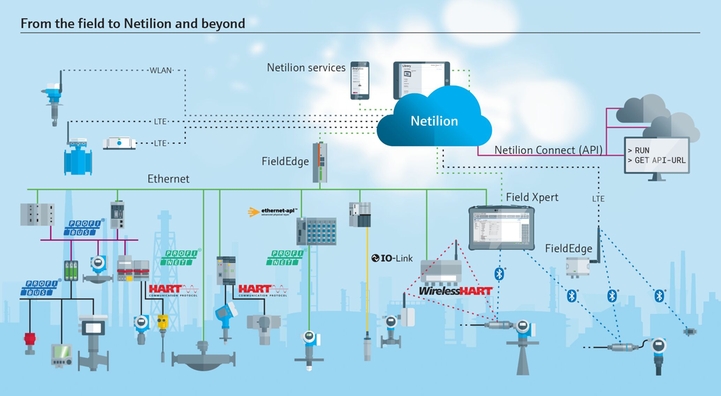

- Rely on communication protocols such as WirelessHart

- Leverage the potential of the IIoT solution Netilion

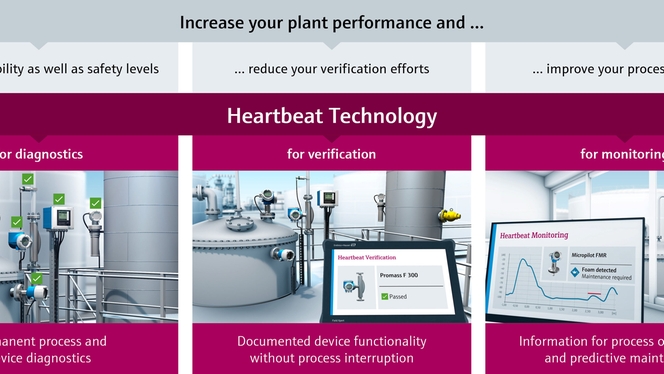

- Optimize maintenance using self-diagnostic Heartbeat technology

Improved functional safety

Automation can be advantageous in the highly competitive global mining industry. However, for automated processes to work reliably, highly dependable and accurate instrumentation is required.

Our expertise in the field

Endress+Hauser offers a comprehensive range of Safety Integrated Level (SIL) instruments covering all critical measuring tasks.

- Integrate field instruments which can be used in HAZOP defined Safety Instrumented System (SIS) zones

- Comply with safety guidelines under IEC 61511

- Leverage instrumentation achieving up to Safety Integrity Level (SlL) 3

Benefits

When safety is concerned, you need to have trust - trust in your equipment, trust in your processes and trust in the partners you are working with. Endress+Hauser has been working in the mining industry for more than 60 years now. Thanks to the experience we have build up together with our customers, we have developed a portfolio of instruments, products and services that were developed with the challenging conditions typical for the mining industry.

Legfontosabb tények

90%

of our instrumentation portfolio is digital or has digital capabilities

Legfontosabb tények

SIL 3

is the highest level our instruments can achieve

Legfontosabb tények

~ 1,600

asset, process and diagnostics data points available

How we can help

Endress+Hauser offers a fully SIL compliant portfolio of analog and digital instrumentation both to enhance the safety of handling, and to optimize the use, of the hazardous substances such as fuel, chemicals, acids, and explosives that are so often essential to mining operations. All technologies are robust to withstand harsh environments, enabling reliable automation.

- Inventory monitoring for optimized materials usage and managed costs

- Remote monitoring for reduced exposure to risks

- Robust instrumentation for functional safety in any environment