Industrial water treatment is an essential activity in a multitude of sectors. The challenge for plant operators is to reconcile efficiency and safety by optimizing treatment costs for industrial water without endangering its intended use within a process. From cooling or steam in production, to specified process water, to direct human consumption, treatment needs vary for quality, composition and pH. Our industrial water treatment portfolio enables efficiencies in any situation.

Legfontosabb tények

20%

of the global water consumption

can be traced back to industries. In developed countries this number is significantly higher.

Industrial water treatment processes

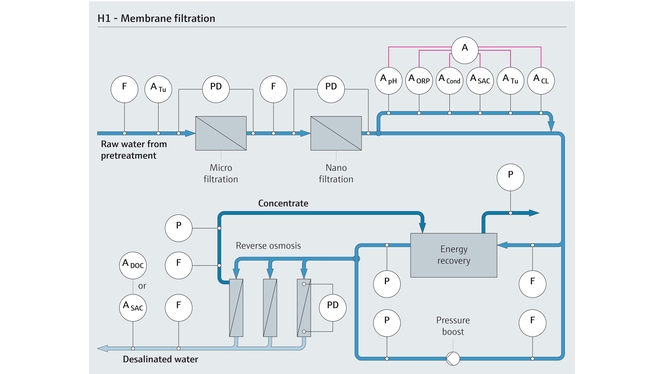

Membrane filtration

A unique technology for water treatment, membrane filtration can be applied to achieve different targets, with varying pore sizes enabling the mechanical separation of bacteria or viruses up to single ions for desalination. Membrane filtration efficiency and lifespan depends upon regular monitoring of multiple water parameters.

Our expertise in the field

Both broad and highly versatile, the Endress+Hauser instrumentation portfolio enables accurate and reliable monitoring of parameters for optimal membrane efficiency and lifespan:

Cooling and boiling water

Corrosion, fouling, and scaling hamper the effectiveness of cooling and boiling processes and can cause severe health problems. Filtration of cooling water, and dosing with biocides to prevent the growth of algae, fungi, and bacteria, are standard practices. Effectiveness of these processes depends upon reliable, ongoing monitoring of water parameters such as pH and oxygen levels.

Our expertise in the field

Our portfolio for liquid analysis includes digital sensors and transmitters, as well as customizable analytical panels for dependable monitoring of key parameters:

- Analyze water quality with Memosens technology

- Monitor with precision all critical control points using Liquiline transmitter systems

- Simplify analytical measuring tasks with customizable analytical monitoring panels

Process water treatment

Process water used directly in end products must consistently conform to specific characteristics for ongoing product quality. Parameters such as pH, turbidity and oxygen levels must be guaranteed through filtration and the addition of precise doses of chemical agents.

Our expertise in the field

Our portfolio of flowmeters, digital analytical sensors and transmitters enables conformity to process water specifications:

- Dose chemical agents with precision using flowmeters

- Monitor safely process outcomes with Memosens technology

Benefits

Endress+Hauser has more than 60 years of experience when it comes to the water industry. All over the world, municipal and industrial customers trust the expertise of our employees and our dedicated portfolio that was designed with the challenges of our customers in mind. We can help you to assure plant availability, product quality and cost effectiveness.

Legfontosabb tények

+60 years

of experience in the water and wastewater industry

Legfontosabb tények

250,000

digital analytical sensors installed worldwide

Legfontosabb tények

40%

longer service life of our digital sensors

How we can help

Endress+Hauser offers a broad portfolio tailored specifically to the unique and varied challenges of industrial water treatment. Our measuring technologies enable our customers to improve process safety and efficiency:

- Membrane filtration

- Cooling and boiling of water

- Process water treatment for specific requirements