Specifikációk áttekintése

-

Accuracy

up to 0.4 mm

-

Process temperature

-200°C...200°C

(-328°F...392°F) -

Process pressure / max. overpressure limit

0,2...6 bar abs

-

Max. measurement distance

36 m (118 ft)

-

Main wetted parts

316L, AlloyC276, PTFE

Alkalmazási terület

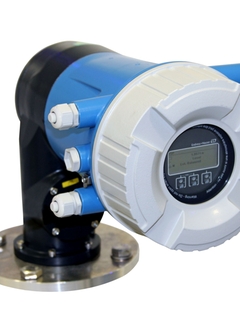

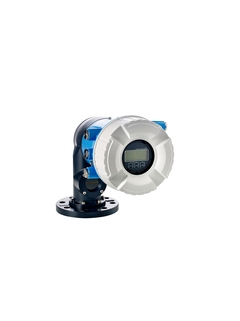

The intelligent tank gauge Proservo NMS80 is designed for high accuracy liquid level measurement in custody transfer and inventory control applications with NMi- and PTB-approvals. It meets the relevant requirements according to OIML R85 and API 3.1B. It fulfills the exact demands of tank inventory management and loss control and is optimized in regards of total cost saving and safe operation.

For high accuracy custody transfer measurement in crude oil, gasoline, diesel, petrochemicals and chemicals.

Process connections: Flanges

Temperature: -200 to +200°C (-328 to +392°F)

Pressure: 0 to +6bar (0 to +87psi)

Maximum measuring range: 36m (118ft)

Accuracy: ±0.4mm (±0.02")

International explosion protection and custody transfer certificates, overfill prevention WHG, SIL

Előnyök

-

Hardware and software developed according to IEC 61508 up to SIL3 (in homogeneous redundancy) for high level of safety

-

Maximum reliability through accuracy up to ±0.4mm (±0.02")

-

Developed according to international metrology recommendations such as OIML R85 and API MPMS

-

Local and country-specific certifications like NMi or PTB for custody transfer applications

-

Simplified installation and trouble-free operations due to easy connection to major DCS systems via open protocols

-

Measurement of interfaces between up to three liquid layers, tank bottom, spot, and profile densities

Videók

Xpert választék

-

Speciális termékek

- Nagy igénybevétellel járó alkalmazásokhoz tervezve

Műszaki kiválóság

Egyszerűség

Kombinálható

-

Egyszerű termékek

- Könnyen kiválasztható, telepíthető és kezelhető

Műszaki kiválóság

Egyszerűség

-

Alaptermékek

- Megbízható, robusztus és kevés karbantartást igényel

Műszaki kiválóság

Egyszerűség

-

Felső kategóriás termékek

- Rendkívül funkcionális és kényelmes

Műszaki kiválóság

Egyszerűség

-

Speciális termékek

- Nagy igénybevétellel járó alkalmazásokhoz tervezve

Műszaki kiválóság

Egyszerűség

Kombinálható

| FLEX választék | Műszaki kiválóság | Egyszerűség |

|---|---|---|

Fundamental választék Eleget tesz az Ön alapvető mérési igényeinek |

Műszaki kiválóság

|

Egyszerűség

|

Lean választék Könnyen kezeli az Ön alapvető folyamatait |

Műszaki kiválóság

|

Egyszerűség

|

Extended választék Innovatív technológiákkal optimalizálja az Ön folyamatait |

Műszaki kiválóság

|

Egyszerűség

|

Xpert választék Megoldás az Ön legnagyobb kihívást jelentő alkalmazásaihoz |

Műszaki kiválóság

|

Egyszerűség

Kombinálható |

Loading alternative products

Loading alternative products

Előd

-

-

Beépítési útmutató (EA)

Wire drum, measuring wire unit, Servo

Angol változat - 06/2022

Proservo NMS8x

EN HU 23/06/2022Nyelv:

Angol

Változat:

23/06/2022

Fájlméret:

2.1 MB

Fájlnév:

EA01434GEN_0122-00.pdf

-

-

-

Műszaki információ (TI)

TI Proservo NMS80

Tank Gauging

EN HU 27/12/202425/10/202310/11/202205/08/202013/07/2018Nyelv:

Angol

Változat:

27/12/2024

Fájlméret:

5.4 MB

Fájlnév:

TI01248GEN_0824-00.pdf

-

-

-

Használati útmutató (BA)

BA Proservo NMS80

Tank Gauging

EN HU 27/12/202425/10/202310/11/202205/08/202013/07/2018Nyelv:

Angol

Változat:

27/12/2024

Fájlméret:

13.1 MB

Fájlnév:

BA01456GEN_0824-00.pdf

-

-

-

Eszközparaméter (GP)

GP Proservo NMS80

Tank Gauging

EN HU 27/12/202417/02/202320/07/201829/06/201701/03/2016Nyelv:

Angol

Változat:

27/12/2024

Fájlméret:

4.2 MB

Fájlnév:

GP01074GEN_0624-00.pdf

-

-

-

Rövid útmutató (KA)

KA Proservo NMS80

Tartálymérés

EN HU 27/12/202417/11/202310/11/202205/08/202030/07/2018Nyelv:

Magyar

Változat:

27/12/2024

Fájlméret:

6.4 MB

Fájlnév:

KA01200GHU_0724-00.pdf

-

-

-

Beépítési útmutató (EA)

SD card with holder Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN HU 30/09/201730/11/2016Nyelv:

Angol

Változat:

30/09/2017

Fájlméret:

1 MB

Fájlnév:

EA01184GA2_0217.pdf

-

-

-

Beépítési útmutató (EA)

O-ring, Servo Installation Instructions

Proservo NMS8x

EN HU 24/10/2017Nyelv:

Angol

Változat:

24/10/2017

Fájlméret:

3.2 MB

Fájlnév:

EA01235GF3_0117.pdf

-

-

-

Beépítési útmutató (EA)

Housing filter Installation Instructions

Micropilot, Proservo, Tankside Monitor

EN HU 28/02/201830/11/2016Nyelv:

Angol

Változat:

28/02/2018

Fájlméret:

404 KB

Fájlnév:

EA01183GA2_0218.pdf

-

-

-

Beépítési útmutató (EA)

Display set, display holder Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN HU 30/11/2016Nyelv:

Angol

Változat:

30/11/2016

Fájlméret:

1.1 MB

Fájlnév:

EA01185GA2_0116.pdf

-

-

-

Beépítési útmutató (EA)

Terminal set Installation Instructions

Micropilot NMR8x; Proservo NMS8x; Tankside Monitor NRF81

EN HU 30/11/2016Nyelv:

Angol

Változat:

30/11/2016

Fájlméret:

1 MB

Fájlnév:

EA01186GA2_0116.pdf

-

-

-

Beépítési útmutató (EA)

Cover, cover clamp, O-ring Installation Instructions

Microwave Level Measurement

EN HU 14/12/201830/11/2016Nyelv:

Angol

Változat:

14/12/2018

Fájlméret:

900.5 KB

Fájlnév:

EA01176GA2_0218.pdf

-