Specifikációk áttekintése

-

Accuracy

repeatablity 0,1%

-

Process temperature

-80°C...200°C

-112°F...392°F -

Process pressure / max. overpressure limit

Vacuum ... 100 bar

(Vaccum ... 1450 psi) -

Max. measurement distance

0.42 m ... 10.0 m

(1.38 ft ... 33 ft) -

Main wetted parts

Insulation material: FEP,PFA

316L

Alkalmazási terület

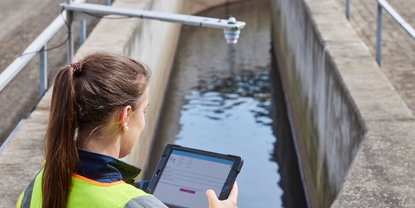

Liquicap FMI52 is a reliable fully insulated rope probe for continuous level monitoring in liquids, particularly in small tanks, build-up forming media and extremely high temperatures - especially for large measuring ranges. The measurement is independent of the dielectric constant (dc). Used in conjunction with Fieldgate FXA320 (remote measured value interrogation using Internet technology), Liquicap is an ideal solution for Inventory Management Solutions.

Device is independent of the dielectric constant (dc) as of a liquid conductivity of 100μS/cm and allows measurement of various liquids without the need for recalibration.

Process connections: Flanges and threads

Process pressure: Vacuum to +100bar (vacuum to 1,450psi)

Measuring range: 0.42 to 10.0m (1.38 to 33ft)

Temperature: -80 to +200°C (-112 to +392°F)

International explosion protection certificates, overfill prevention WHG, SIL, hygienic certificates, marine approvals

Előnyök

Use also in safety systems requiring functional safety to SIL2 in accordance with IEC 61508

Reliable and universal application thanks to wide range of certificates and approvals

No calibration necessary (factory preconfiguration). No calibration necessary for media with a conductivity of 100μS/cm and higher

Material in contact with the process made of corrosion-resistant material

Menu-guided local configuration via plain text display (optional)

Two-stage overvoltage protection

Videók

Extended választék

-

Felső kategóriás termékek

- Rendkívül funkcionális és kényelmes

Műszaki kiválóság

Egyszerűség

-

Egyszerű termékek

- Könnyen kiválasztható, telepíthető és kezelhető

Műszaki kiválóság

Egyszerűség

-

Alaptermékek

- Megbízható, robusztus és kevés karbantartást igényel

Műszaki kiválóság

Egyszerűség

-

Felső kategóriás termékek

- Rendkívül funkcionális és kényelmes

Műszaki kiválóság

Egyszerűség

-

Speciális termékek

- Nagy igénybevétellel járó alkalmazásokhoz tervezve

Műszaki kiválóság

Egyszerűség

Kombinálható

| FLEX választék | Műszaki kiválóság | Egyszerűség |

|---|---|---|

Fundamental választék Eleget tesz az Ön alapvető mérési igényeinek |

Műszaki kiválóság

|

Egyszerűség

|

Lean választék Könnyen kezeli az Ön alapvető folyamatait |

Műszaki kiválóság

|

Egyszerűség

|

Extended választék Innovatív technológiákkal optimalizálja az Ön folyamatait |

Műszaki kiválóság

|

Egyszerűség

|

Xpert választék Megoldás az Ön legnagyobb kihívást jelentő alkalmazásaihoz |

Műszaki kiválóság

|

Egyszerűség

Kombinálható |

Loading alternative products

Loading alternative products

Előd

-

-

Műszaki információ (TI)

TI Liquicap M FMI52

Capacitive

EN HU 14/02/202501/04/2021Nyelv:

Angol

Változat:

14/02/2025

Fájlméret:

1.4 MB

Fájlnév:

TI01521FEN_0325-00.pdf

-

-

-

Műszaki információ (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN HU 06/12/202425/03/202415/09/202328/10/202130/07/2021Nyelv:

Angol

Változat:

06/12/2024

Fájlméret:

1.3 MB

Fájlnév:

TI00426FEN_2624.pdf

-

-

-

Műszaki információ (TI)

Technical Information Liquicap M FMI51, FMI52

Capacitance level measurement

For continuous measurement in liquidsEN HU 22/06/201728/08/201212/01/201104/04/200701/09/2006Nyelv:

Angol

Változat:

22/06/2017

Fájlméret:

1.5 MB

Fájlnév:

TI00401FEN_1517.pdf

-

-

-

Használati útmutató (BA)

Liquicap M FMI52 PFM

Capacitive

EN HU 01/04/202123/03/2020Nyelv:

Angol

Változat:

01/04/2021

Fájlméret:

1.5 MB

Fájlnév:

BA01986FEN_0221.pdf

-

-

-

Használati útmutató (BA)

Liquicap M FMI52 HART

Capacitive

EN HU 01/04/202123/03/2020Nyelv:

Angol

Változat:

01/04/2021

Fájlméret:

2.3 MB

Fájlnév:

BA02021FEN_0221.pdf

-

-

-

Használati útmutató (BA)

Liquicap M FMI51, FMI52 FEI57C PFM Operating Instructions

Capacitance level measurement

Valid as of software version:

FW: V 01.00.00

HW: V 01.00EN HU 22/06/201712/01/201127/07/200719/12/2005Nyelv:

Angol

Változat:

22/06/2017

Fájlméret:

1.3 MB

Fájlnév:

BA00297FEN_1417.pdf

-

-

-

Használati útmutató (BA)

Operating Instructions Liquicap M FMI51, FMI52 FEI50H HART

Capacitive level measurement

EN HU 22/06/201712/01/201130/01/200719/12/2005Nyelv:

Magyar

Változat:

22/06/2017

Fájlméret:

2 MB

Fájlnév:

BA00298FHU_1417.pdf

-

-

-

Rövid útmutató (KA)

Liquicap M FMI52 HART

Kapacitív

EN HU 01/08/202101/04/202101/02/2021Nyelv:

Magyar

Változat:

01/08/2021

Fájlméret:

1.2 MB

Fájlnév:

KA01454FHU_0321.pdf

-

-

-

Rövid útmutató (KA)

Liquicap M FMI52 PFM

Kapacitív

EN HU 01/09/202101/04/202101/02/2021Nyelv:

Magyar

Változat:

01/09/2021

Fájlméret:

855.3 KB

Fájlnév:

KA01455FHU_0321.pdf

-

-

-

Beépítési útmutató (EA)

Cover for housing T13 terminal compartment Installation instruction

Liquiphant M/S, Soliphant M, Liquicap M, Solicap M/S

EN HU 24/02/202215/08/201409/08/2012Nyelv:

Angol

Változat:

24/02/2022

Fájlméret:

119 KB

Fájlnév:

EA01050FA2_0322.pdf

-